Fiber optic cable jacket material

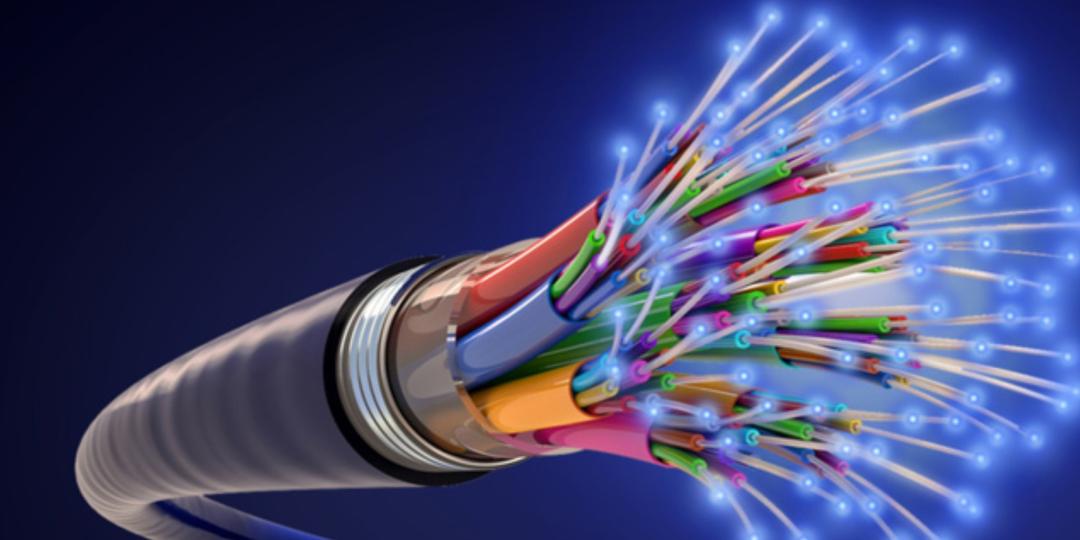

The cable jacket provides the first line of defense against the surrounding environment. It resists water entry while remaining inert to gases and liquids that the cable may be exposed to during its service life. It provides a smooth, low-friction surface for cable placement. The jacket must be made of a material that will allow the cable to remain flexible and serviceable at all the temperatures it will experience during its lifetime.

It must resist abrasion during installation. It must provide, along with the cable's strength members, the mechanical strength required to survive its environment and installation forces. For indoor cables, the jacket also provides the fire retardance required by building codes.

Many different materials are available for cable jacketing making it possible to match the jacket material to the end user application requirements. The table below provides a listing of some of the more popular jacketing materials used for optical cables.

PE - 1 Polyethylene (MDPE - medium density PE / HDPE - high-density PE)

- Primary outside jacket material.

- Good resistance to UV (sunlight) due to carbon black.

- Good flexibility over a wide range of temperatures.

- Good abrasion and crack resistance.

PVC - Polyvinyl chloride

- Provides good mechanical protection.

- Flexible at normal installation temperatures.

- Flame retardant. (typical riser material)

- Used for many indoor applications.

- Can be protected against sunlight with various UV inhibitors.

LSZH - Low smoke, zero halogen

- Flame Retardant with low smoke and no halogenated materials

- For use in unventilated areas exposed to public, subways, and tunnels.

- Good mechanical performance.

Most Outside Plant optical cables are made from medium-density or high-density polyethylene with carbon black for UV stabilisation. In North America, the National Electric Code dictates that this type of cable jacket cannot penetrate any building by more than 15 meters. A fire retardant, the listed cable must be used for indoor applications. Often a riser-rated PVC jacket is used for indoor/outdoor cables that must penetrate the building is more than 15 meters.

Subscribe to our newsletter

Stay up to date with our latest news and product releases by subscribing to our newsletter.

We respect your privacy and you may unsubscribe at any time.